This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

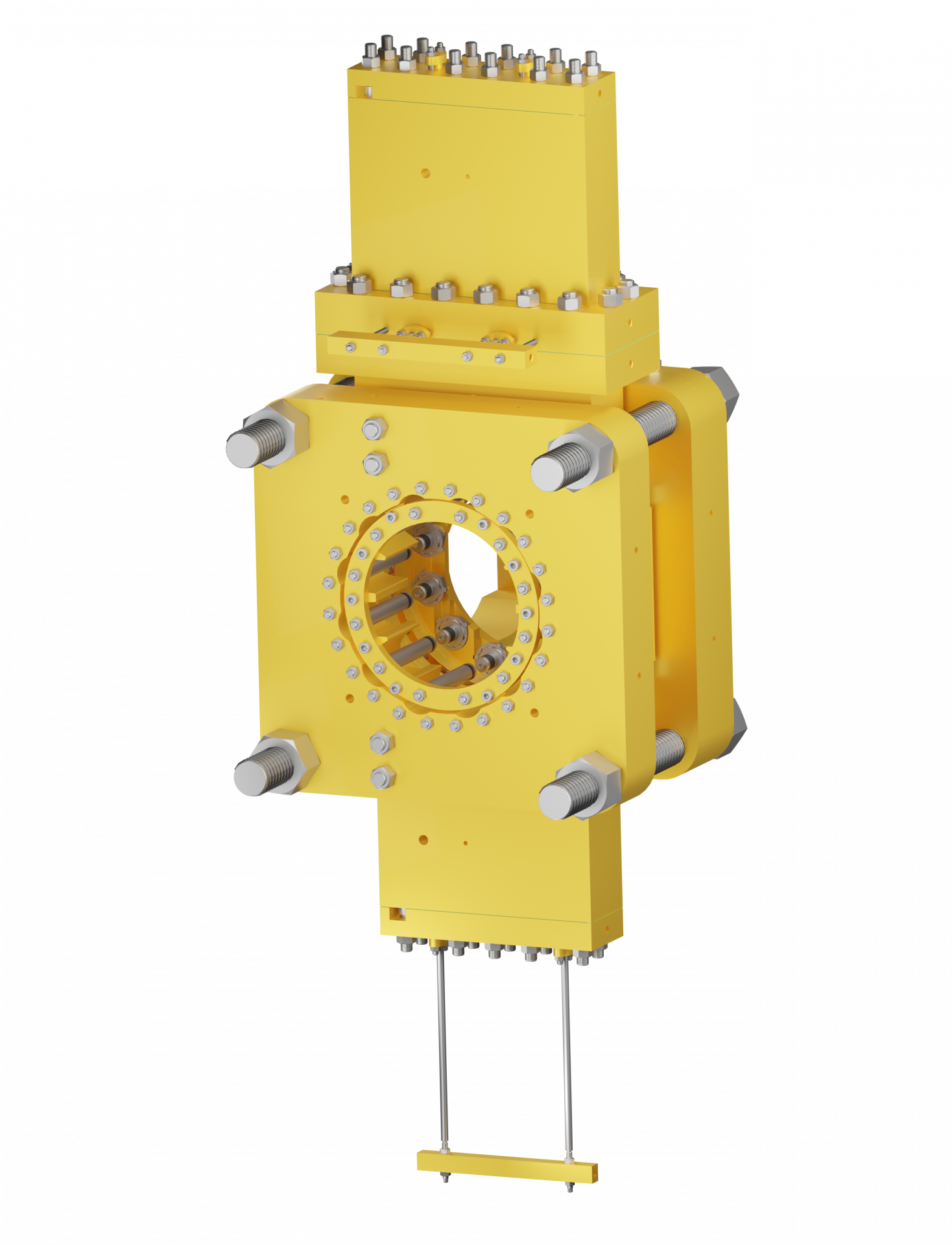

AOGV 06C400

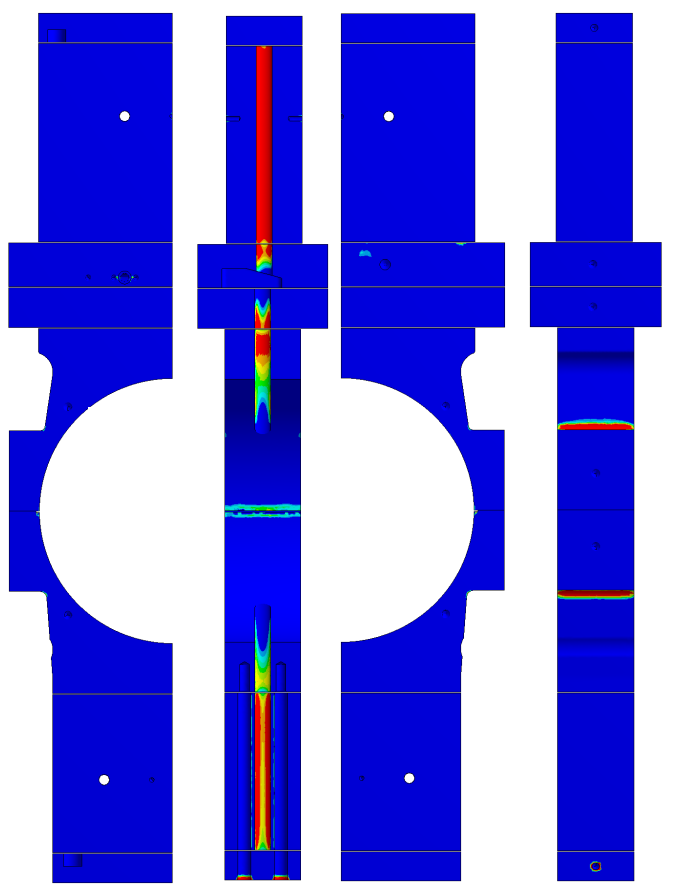

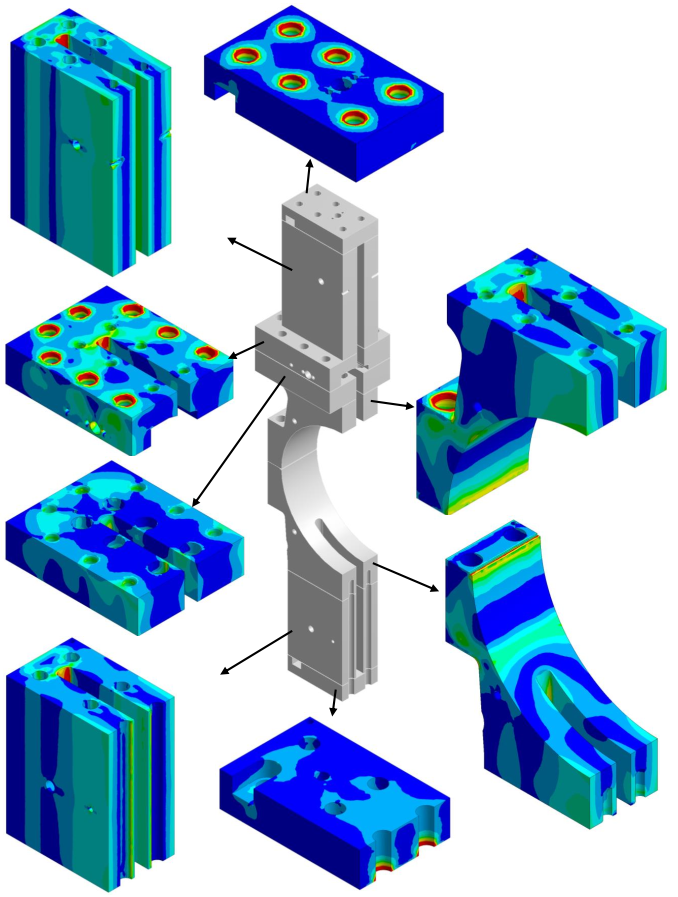

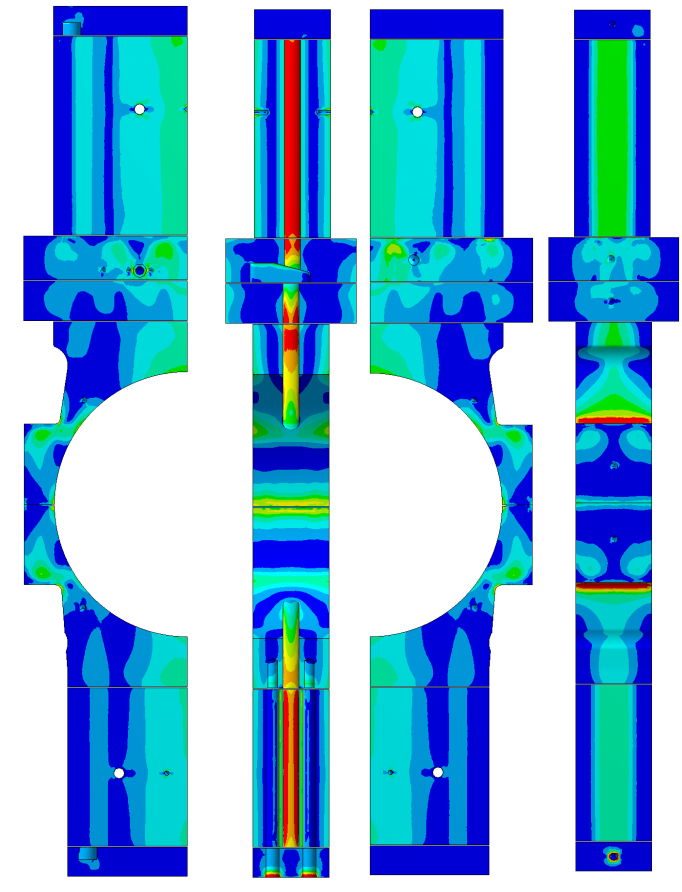

An IK Engineering-designed 6″ Class 400 AOGV was utilized for operations in the USA. The cast iron ball valve, which prevented internal leakage and maintenance on one of three pumps in a refinery’s cooling system, was causing operational issues. Two pumps could not adequately cool the entire plant, so a conventional shutdown was planned to replace the valve. However, it provided a purpose-built AOGV mechanical isolation tool that allowed the leaking valve to be isolated from the system. This enabled the customer to conduct maintenance without disrupting production. IK Engineering played a crucial role in the design and production process.

Scope of work for IK Engineering

- 3d scanning preparation of location

- Design of 6” Class 400 AOGV

- Project documentation

- Bids collection and production coordination

- Production follow-up, reporting, and quality control

1303 mm x 565 mm x 565 mm

[51.3 in 22.25 in x 22.25 in]

590 kg / 1300 lbs

ASME B16.5 class 150

PED 2014/68/EU/ – EN 13445

50 bar / 725 psi

-29°C to +200 °C / -20°F to +392°F

Pressure Steel

SPW ASME B16.20

Contact us

Our friendly team would love to hear from you.